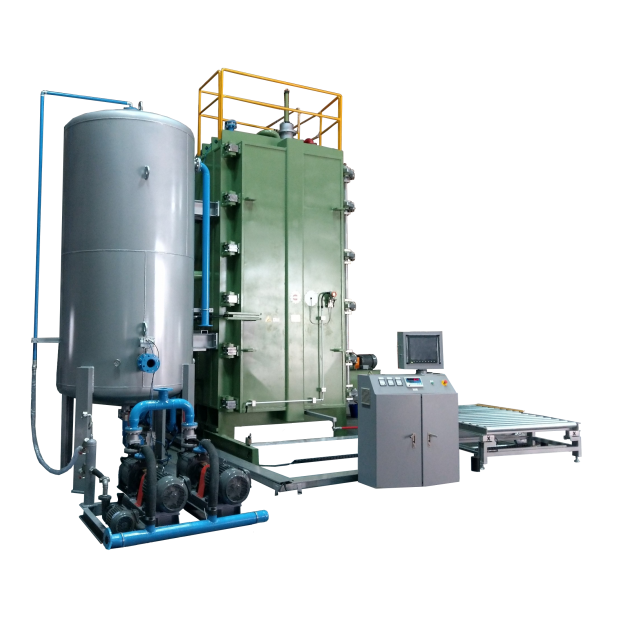

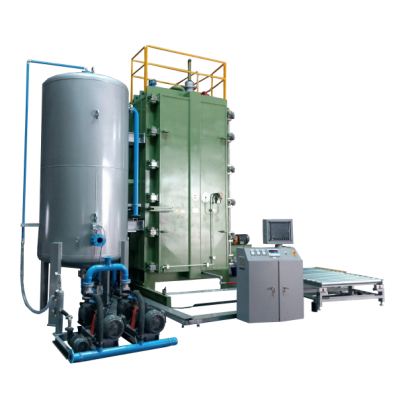

109 Automatic Vacuum Block Molding Machine SFM-2000

Mechanical body

The body has been treated with sandblasting, zinc-aluminum spraying, waterproof primer and surface paint.

Both the inside and outside of the foam barrel are made of 304 stainless steel laser cutting, and the compartments are insulated.

Air pipes are hot-dip galvanized.

The tripods are sandblasted and then painted.

Mainly use imported parts from Germany FESTO.

Use Taiwan TECO IE series energy-saving motors.

Control System

Using Japan's intelligent graphics fast man-machine interface and PLC programmable logic controller, easy to operate.

The pressure required by the machine can be adjusted directly through the man-machine interface.

The production parameters and time can be memorized, and the process can be started quickly.

Fully automatic, semi-automatic, intermediate start, manual operation can be performed.

Security System

Door guards.

Over-temperature protection device.

Overpressure protection device.

Power failure protection system.

Phase loss protection automatic power-off system.

Other Systems

This machine adopts tuning fork induction and photoelectric material level control.

Electronic weighing system.

vacuum system.

Temperature Control System.

Remarks: Customized models can be provided according to customer needs, and the product specifications are mainly based on the final contract.

AB-3750 EPS Automatic Vacuum Block Molding Machine

AB-3750 EPS Automatic Vacuum Block Molding Machine 109 Automatic Vacuum Block Molding Machine SFM-2000

109 Automatic Vacuum Block Molding Machine SFM-2000