wE persist in GIVING YOU THE BEST MACHINE

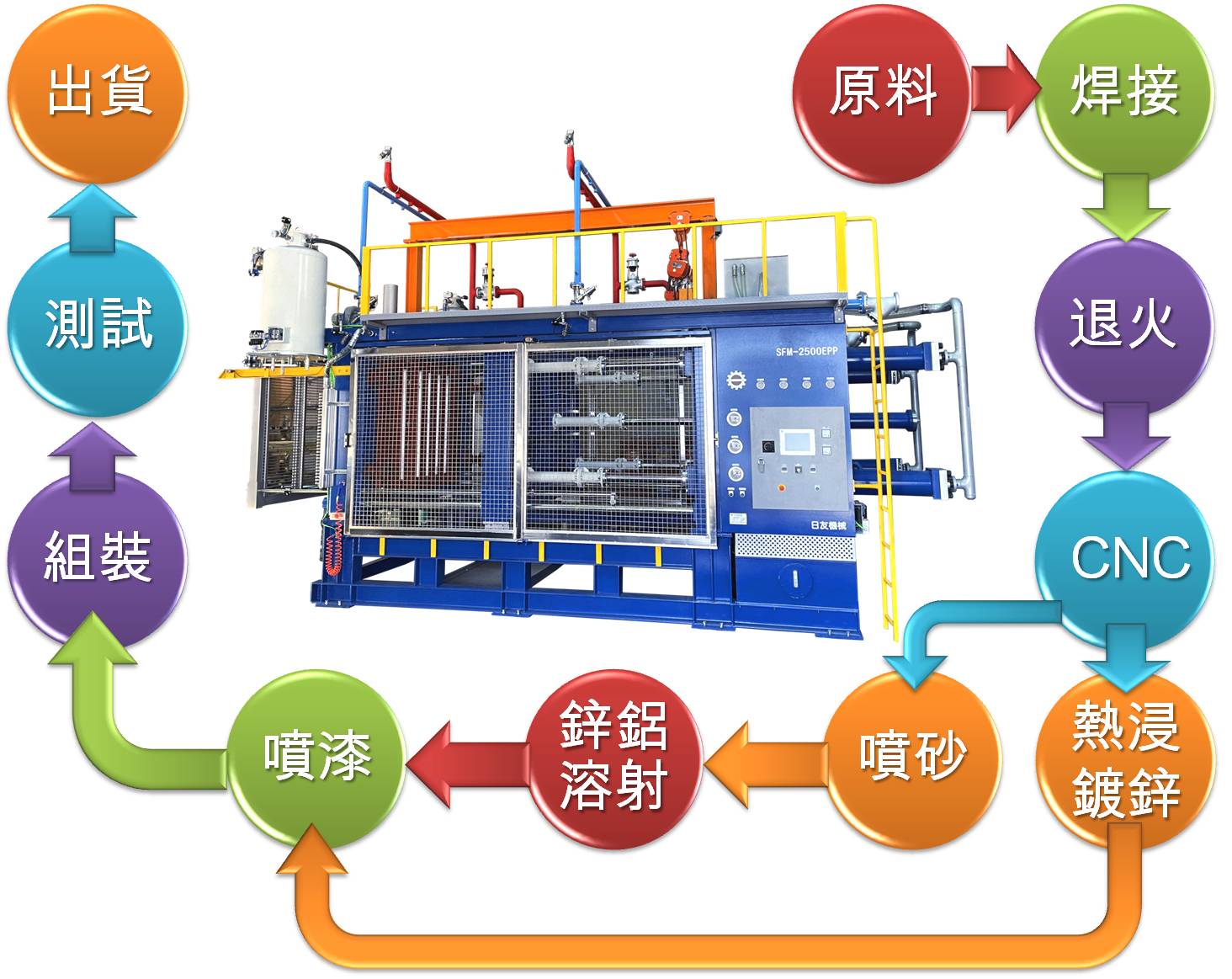

EPP/EPS Machine Manufacture Procedure:

※ After the delivery of the first-grade raw materials of China Steel Corporation, the engineer will weld the shape of the machine,

and arrange for annealing after the welding is completed,so as to restore the shape and details of the machine and stabilize the size.

※ After the annealing is completed, CNC machining is carried out to facilitate the precise size of each part of the machine and make the subsequent mold clamping more accurate.

※ After CNC processing, the anti-rust mechanism will be arranged according to the customer's choice.

You can choose to arrange sandblasting and zinc-aluminum spraying, or arrange hot-dip galvanizing.

※ After the anti-rust mechanism is completed, a double-layer coating of waterproof primer and surface paint will be carried out to extend

the durability of the machine.

※ After the completion of the double-layer coating, the assembly of various detailed equipment parts and control systems will be carried

out immediately. After the installation is completed,the machine operation test will be arranged.

※ After the test is completed, the machine can be delivered to the customer, the piping and machine installation can be carried out according to

the time agreed with the customer,and the production can be launched after completion.